So you've got five (or four, or six) wires. Your motor's going to have two halves, and you can probably even tell just by looking which side each wire belongs to. If you're only looking at four wires, you're in luck - it's a bipolar motor. All you have to do is figure out which two pairs of wires go together. If you've got a unipolar motor, or more than 4 wires, you're going to have to break out your ohmeter.

What you're looking for is the common (ground) wire for each half. You can tell which is ground in a bipolar motor because it has half the resistance to either of the poles than the poles do across themselves. Pictured is my notes from hooking up wires to wires and noting the resistance (or if they're connected at all). You can see that White is the ground for the bottom trio b/c it has half the resistance to Red or Blue that they have to each other. (This motor's strange and doesn't have a center tap on the top magnet coil. It's like it's half-bipolar, half-unipolar. Maybe you could use this to sense rotation in the Red-White-Blue coil when the Black-Yellow coil is being driven.).

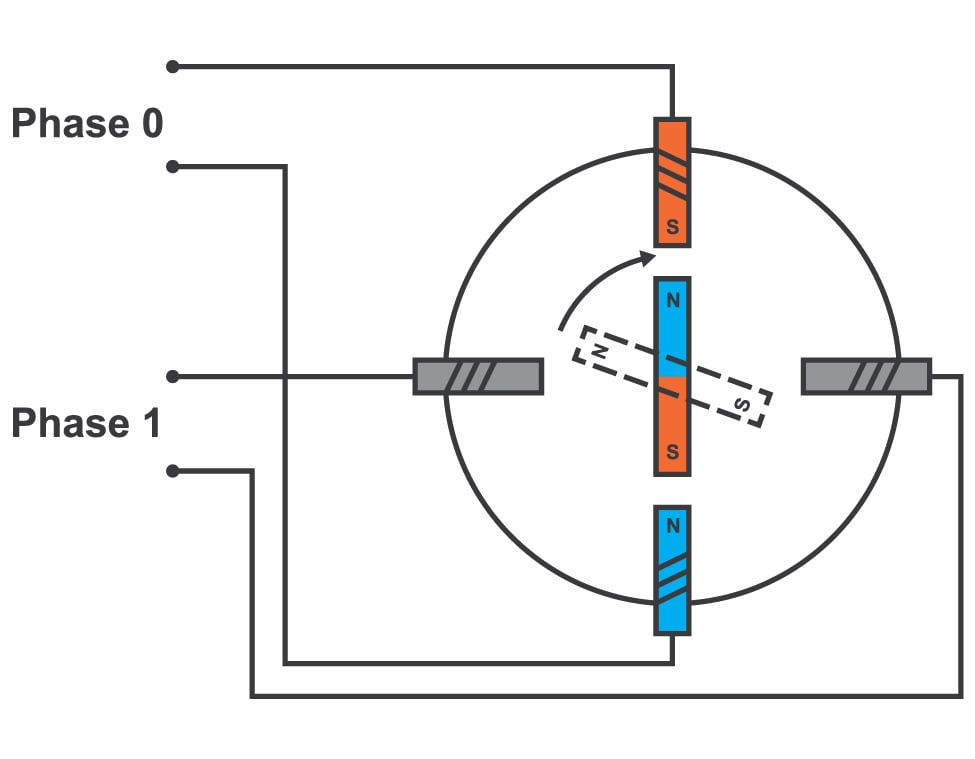

I was going to drive this motor as a bipolar one, so I'm ignoring the White ground wire. I've only got four wires to worry about. You might want to run your unipolar motor as bipolar anyway, because it uses the whole coil in both phases instead of alternating between the two halves of each coil.

More coil = more torque. Run current through a pair (noting the polarity you chose) and then run current through the other pair at the same time. When you hook up the second pair, watch which way the motor turns.

Write this down. Now reverse the polarity on the first pair you chose. Then hook up the second pair again with their polarity also reversed.

Note the direction. From this you should be able to figure out the sequence for rotating the motor in either direction. In my example, both ended up turning counterclockwise, so stepping through the sequence in the same way I chose will step the motor CCW. So far so good. Only problem is that the motor doesn't seem to have all that much torque, which could be due to the fact that the microprocessor will only put out 50mA per pin. The obvious next step would be to hook it up to a motor driver to supply it with more juice. But then a little thinkin': I'm only driving it with 5v, and the coil-winding resistance is 125 ohms.

Which means that the motor's only drawing 40mA per pin, and it should be driven just fine by the (beefy!) AVR chip. So to get more voltage driving the motor, I hooked it up to a H-bridge chip. The circuit is pretty simple. Each pin from the AVR goes to an input, and the corresponding output pins go to the motor. The chip needs 5v for the logic section, and can take a lot more voltage in the motor section.

Running it on 11.25v (three 3.6v batteries) helped a bit. Noticeably more torque to my finger, but it's still not a powerhouse. Not bad for a motor which is smaller than a nickel, though. And now the circuit's become a general-purpose bipolar stepper motor driver. Added Nov 29: Ran the motor last night at 12v for a while and it started to get hot.

I'm not sure if it was a resonant frequency problem or if it was simply too much current for the windings. Either way, be a bit careful if you're driving this little motor with bigger voltages. Multiple stepper drivers is the way to go. (Not sure you need multiple 'boards', but at least multiple driver ICs.) When you start doing anything times four or times twelve, it can easily bog your microprocessor down, especially if you're doing 'fancy' motion control stuff like acceleration and deceleration. The best way around that is to offload as much as you can to purpose-built silicon.

And if you decide to get even fancier, you can dedicate one micro per motor or section-that-requires-coordination. Then you can use a master controller to run all the sub-controllers.

This gets rapidly out of the realm of quick-and-dirty hacks though, and into engineering. Are you sure you want to drive stepper motors?

Can you do something with a DC motor and position sensors? To run DC motors, you just need to apply power. If you need speed control, you can use PWM. Nerdkits has a good tutorial on running DC motors, for instance.

(I'm writing a book on AVR programming at the moment with two chapters on motor control, but it won't be out until summer.) Also see sites like Robot Room and Dallas Personal Robotics Group - you'll need slightlly more complex circuitry if you'd like the motor to go both forwards and backwards. (There, again, a few dollars spent in motor driver chips is easily worth the hassle, IMO, but it's also fun to DIY.) Slowing a DC motor down as much as you'd like to requires a gear train, which can be a pain to assemble. On the other hand, if you're slowing a DC motor down from a few thousand RPM to just a few, you'll get a tremendous gain in usable torque, so I'd say it's worth the tradeoff. And if you put your encoders upstream of the geartrain, you get an equivalent gain in measurement resolution, which can help if you need the motors to stay in synch. As you generally need 4 wires to drive a stepper and 2 wires for serial, it is a bit difficult but not impossible to do it on an attiny85.

Simply install softserial and read the data that comes in and translate that to steps. I havent checked it myself and not sure how big the softserial code is, but I guess it would fit. Also, it is possible to drive a unipolar stepper motor with only 2 pins Now although as I said this is all possible, you could wonder if you should do it, with a pro mini available at 1.60 euro that might be a better choice. Would be good. If you're serious, you usually start off with an idea of how much torque and speed you need for your application, then find a motor that'll deliver, and then pick a motor driver depending on the motor's current requirements. But for low-current applications, I've had good luck with the SN754410, for slightly larger currents the 293D is good, and above that, especially if you're driving with a microcontroller or need microstepping, Allegro has some great offerings.

And there's always build-it-yourself from 8 MOSFETs. Google for 'H-bridge' to get an idea.

12V bi-directional 4-phase unipolar stepper motor with a 1.8 degree step angle (200 steps per revolution) with a 5mm shaft. Holding torque is 830g cm (8.14Ncm) Coil resistance 75 Ohms Current per coil 160mA Phase inductance 60 mH 12V rating 6 leads Winding 1 = Brown A, White O and Red A! Winding 2 = Orange B, Black O, Yellow B!

The controller is a V4.3 Sparkfun Easydriver Stepper Motor Controller. And I am using a Picaxe 18M2 for the signal. At first this thing was totally unruley and just twitched and hummed and what sometime span a little. When it did spin i could change the direction as I wanted to, though sometime this changed the speed! Sometimes it didnt go anywhere in one direction and span when I changed the direction. Then i came across a comment about the GND pin, and wired this to the microprocessor to cure that. All the way through this I have foudn it hard work to understand how to wire it together.

The datasheet for the motor was a 5 minute photocopied sketch, and I could only understand about 10-20% of the easydriver datasheet. I have search around here and on the picaxe forums and followed a couple of guides, which has brought me to the following stage. I have 12V from a 3.2A supply going into the PWR IN pins on the driver. I have a push button wired between the +5V pin and the DIR pin on the driver. I have a wire running from the GND pin to the GROUND pin on the Microprocessor. The two centre wires from the stepper motor go no-where. The two A wires go into header pins on the A pins, and the 2 B wires likewise to the B pins, according to the motor datasheet.

TurboTax Premier Federal State 2016 For Mac Download Version, TurboTax is tailored to your unique situation-it will search for the deductions and credits you deserve at Office Depot &. Intuit Turbotax Premier 2016 [OLD VERSION] Federal and State Fed Efile PC/MAC Disc by TurboTax. Turbotax premier federal state 2016 for mac. Find helpful customer reviews and review ratings for TurboTax Premier 2016 Tax Software Federal & State + Fed Efile Mac download [Amazon Exclusive] at Amazon.com. Read honest and unbiased product reviews from our users. Find great deals for TurboTax Premier 2016 Federal & State E File for PC Mac Turbo Tax. Shop with confidence on eBay! Skip to main content. EBay: Shop by category. Item 3 Intuit Turbotax Basic Tax Year 2016 Windows Mac Federal Returns & E-File -Sealed - Intuit Turbotax Basic Tax Year 2016 Windows Mac Federal Returns & E-File -Sealed.

Finally I have a wire going from the B.1 output pin on the Microprocessor to the STEP pin on the controller. According to this guide: I need 500hz square wave to test this thing, which equates to pause 2 in picaxe language I beleive. So to test it I looped the high to low transition with pause 2 in between like thus. Code: MAIN: pause 2; low b.1; pause 2; high b.1; goto main; Yet all it does is sit there, no humming, no twitching, no spinning, no steps. It resists any attempts to turn it by hand, but doesnt actually go anywhere.

So question 1: Why isnt this working? Is it a code problem?

(The picaxe manual only says how to control the picaxe motor controller, and the code makes no sense to me). I have seen written that by default this thing takes 1/8th steps, Yet on the Datasheet it says for 1/8th mode MS1 and MS2 are high. So does that mean they are tied high? And to change this to full steps or whathave you would I wire these stright to ground? Or via a 10k resistor (I only descoverd pulldown/pull up today, am I in the right area?) any help would be much appreciated! Thanks in advance! Zakari, I'm really glad you got it working, and I apologize for the lack of good examples and documentation for the EasyDriver.

A lot of people use it in a lot of different ways (with different motors and STEP/DIR sources) so there is a lot of possibilities to cover. For being new at this, you've done a wonderful job getting it working.

The MS1 and MS2 inputs to the driver chip are weakly pulled high already on the Easy Driver board. So unless you want to change from 1/8th microstep mode, you don't have to connect anything to them. If you want your motor to move more (in angle) per step (because you have a limited speed input to the STEP pin) you could tie both MS1 and MS2 low (to GND) to put it in full step mode. In order to get faster pulses, you may need to switch away from the PICAxe. Unless it has a command that allows you to do more accurate and fast pulses (that are smooth), you may have just hit the limits of what that system can do.

Using C on my UBW board, I can run my EasyDriver smoothly up to 15,000 steps/s or so with no problem. So the key is getting smooth pulses to the ED that are fast enough for what you need. Maybe there's a frequency output command for PICAXE that would work? Brian Hi As it happens the easydriver was probably the easiest part to find info for. That said an 'idiots guide' to wireing it up would help justify the 'easy' in the name The one on your website was good, perhaps this would be useful in the datasheet? Since getting this working it has started misbehaving again! Now it does nothing enless you fiddle with the output pin on the microprocessor.

I thought at first this was a loose connection but then i observed that it only worked with my fingers, not with a wooden pencil. Touching the pin with lead from the pencil also makes the motor turn slowly, if i touch it with the pliers of my leatherman however, it spins alot faster.

Im assuming there is some sort of currentflow through the conductive materals, but I have no idea why it shouldnot turn when a signal is passing into it, but does when touched by anything conductive. CAn you shead any light on this please? Hello Brian Ive had anothe rplay with this. Im very confused. I put my DVM on the pin ( Black to pin, Red to a 5V supply?) and get a solid reading of 5.04V, I plug a led in and it flashes on and off in the timing I would expect. So I change the code to go back to basics.

Stepper Motor Driver Chip

When disconnected, and running a code that has B.1 high and B.0 low, then switches with a push button, both pins switch between 4.44V and 0.02V (the board is driven from the 5V output on the driver). However if i connect either pin to the STEP pin, the transition is 5.04V high, and 4.78 low. I further notice that if i use a 4.8V battery pack, the normal transition is 4.43 to 1.89V when connected to STEp, and 4.41 to 0.03 when not. This doesnt make alot of sense to me, but is there some sort of current flow coming from the STEP pin?? That motor should work just fine. The best thing for you to do is check out the datasheet for the motor: I'd wire it up as in diagram 2 - in parallel bi-polar mode.

A, A' B and B' go to the Easy Driver motor outputs. You can find out which wires correspond to positions A through H by looking at the table on the next page of the datasheet - just cross reference the model number that you have with each of the positions. Then just hook up the motor as diagram 2 shows, and you'll be good to go. I stumbled onto this thread due to curiousity about the GND pin located next to STEP and DIR on v4.4 board (just received yesterday). I was guessing that I might want to attach a ground between my Microprocessor (ARM Cortex M3) and the ED and after reading this thread I guess that is True?

In most simple form I believe I need only connect 4 motor wires (A+, A-, B+ and B-) along with Step, Dir and Enable (plus a common ground perhaps) and I will have the motor up and running. Is this correct? I'm ok with 1/8 MS, always enabled and never sleeping. I'll actually be using a PC (ATX) power supply to power both the Microprocessor and ED, would it be wise perhaps to instead tie ground pin next to STEP on the ED to the ground of the PC power supply instead? I'm guessing the purpose of this GND pin is to help prevent noise (spikes) from damaging microprocessors.

Stepper Motor Driver Board

BAS, You do not need to connect enable. The bare minimum are the following: Four pins to the motor Two pins to power (+ and GND) Two pins to Micro (STEP and DIR) Since all of the GND pins on the EasyDriver are connected together internally, as long as your micro is outputting 5V pulses to STEP and DIR, and the micro's GND is tied to the power supply GND somewhere in your system, you should be OK. Would it hurt to directly tie the micro's GND to the GND pin on the EasyDriver right next to the STEP and DIR pins?